Ever since we picked out our 42-foot-long, 8 ton fifth-wheel RV, I have been more than a little afraid of it. I’ve tried to live my life so that things don’t matter, but this one thing is our home and holds everything Kellyn and I possess at the moment, save a few items we stored in a rental unit in Colorado. We don’t possess anything particularly valuable, but replacing everything would be a hassle. This home of ours is regularly exposed to extraordinary stresses and danger, each and every time we move it, so having to replace everything at some point does have a very large probability, which serves to emphasize the importance of life, loves, friendships, and experiences over things.

On the road, our rig is (to me at least) an imposing presence, almost the size of an 18-wheeler…

But it is built for lightness, and thus is fragile despite its size and weight.

My mental image is an eight-ton soap-bubble, able to pop at any time.

Until yesterday, the bubble going pop was just conjecture…

The dogs and I were moving from Williamsburg VA to Clarksboro NJ, just outside Philadelphia. Kellyn was in Spokane WA presenting at a SQL Saturday event. We were about 3 1/2 hours into a 5 1/2 hour drive. Since we unmoored from Colorado late last June, we had moved the RV 45 times, as documented on the map page on this website, so this was our 46th move in 40 weeks, which is quite a rapid and sustained tempo when you consider that we both have demanding full-time careers.

Side note: It is funny how many family, friends, and acquaintances think we’re on vacation or retired, and that we have all manner of free time in our lives since we set sail. The reality is that our typical Saturday involves breaking down, driving about 6 hours, and then setting up somewhere, leaving Sunday as our only spare time.

So, it was Saturday and I was traveling on I-95 northbound, just entering the McHenry Tunnel in Baltimore to go beneath the Inner Harbor. As we rolled down the highway ramp toward the tunnel entrance, I glanced over to the passenger-side rear-view mirror and saw a lot of gray smoke obscuring the vehicles following behind me. My immediate thought was, “Some poor bastard is having a really bad day“.

Then I glanced in the driver-side rear-view mirror.

The smoke was coming from our trailer. A great deal of smoke.

This day, the poor bastard was me.

Smoke was billowing in a thick gray cloud from the driver side of the trailer, down by the wheels. It was so thick it completely obscured anyone following, if anyone was following. I couldn’t see flames. I had no idea what was causing the smoke, and also no idea if and when the smoke cloud would burst into flames.

But I couldn’t stop and investigate. We had by now entered the McHenry Tunnel, with traffic piling up behind and roaring past.

I had no choice but to keep going. There was a good chance that the whole thing would catch fire, and I would have an eight-ton bonfire attached to my truck, eventually emerging from the tunnel with just a charred metal base frame.

It was a nightmarish mile. I slowed down in hopes of delaying the outburst of flame, moving at 25 mph with the hazard lights flashing, while the rest of the traffic was passing at 50-60 mph. I didn’t know it, but the smoke was reported to 911 by the other drivers in the tunnel, and the security team at the tunnel had also seen the smoke on their monitors and had already scrambled to investigate. This was not being taken lightly in the post-9/11 reality.

I emerged from the tunnel still smoking (and not yet in flames) and immediately pulled over to the right side of the roadway. This wasn’t a parking area — it was still a travel lane, so I was still in the midst of traffic, although the volume was light enough that I wasn’t really obstructing anyone, yet. I got out of the truck and ran back to the no-longer-smoking trailer to investigate, and this is what I saw…

On the driver side, both wheels were in contact with each other. When the trailer moved, they rubbed against one another as they spun, burning rubber, creating the thick gray smoke. The tires were severely damaged, with deep grooves worn into the tread on each. Fortunately, they had not exploded or deflated yet.

By the way, this is how they are supposed to look…

Further investigation quickly revealed the cause…

This broken mounting bracket secures the leaf-spring of the trailer suspension on which the rear axle is mounted. Here is a reverse-angle view from beneath the trailer, showing the damaged mounting bracket with the leaf spring suspension still attached…

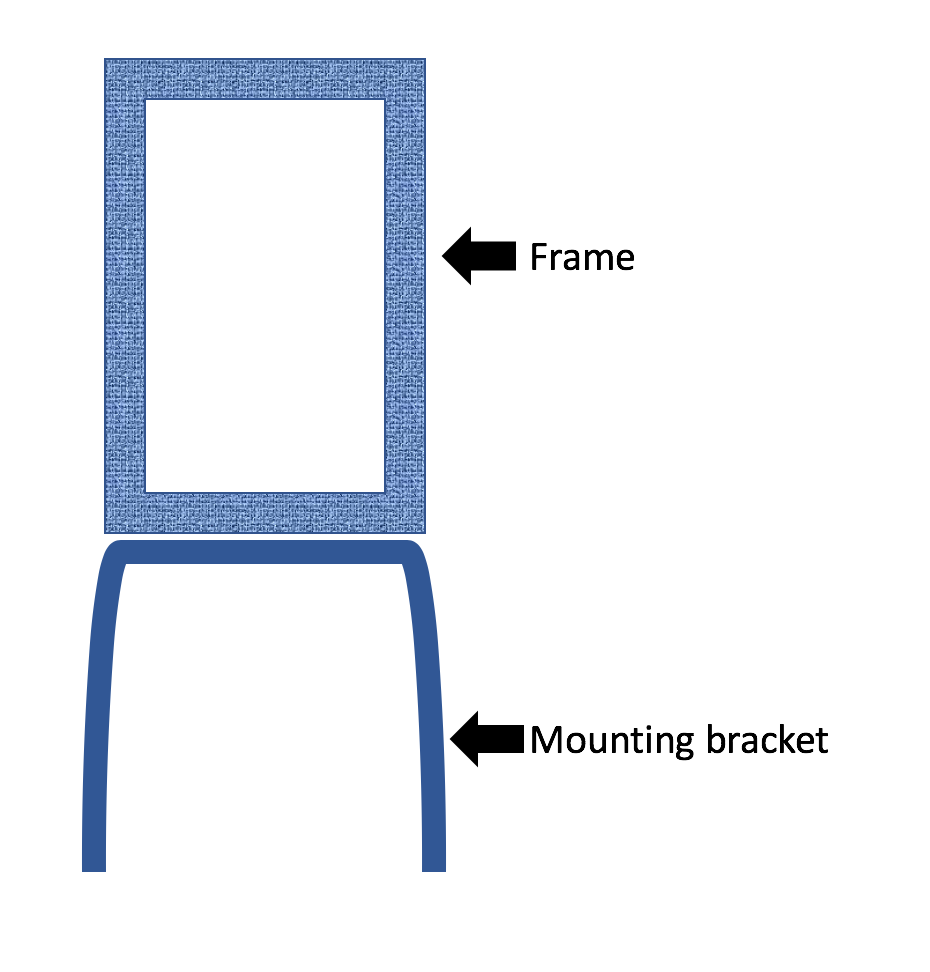

The U-shaped mounting bracket had ripped forward, away from the frame, causing the rear axle to swing forward, allowing the two wheels on the driver side to come in contact. By the way, here is what that same bracket mount is supposed to look like…

This is the same mounting bracket on the passenger side of the trailer. As you can see, it is just a U-shaped piece of metal, holding the end of the leaf-spring between the arms of the “U” and with the base of the “U” welded to the frame.

Anyway, tunnel personnel were on the scene within seconds of my coming to a stop just outside the tunnel. The tunnel was still filled with smoke and the smell of burned rubber, and I know there were some very irritated travelers on I-95 that day. Tunnel security personnel did not permit me to stay parked in the far-right lane just outside the tunnel exit. I was reluctant to move the trailer any further, but they insisted I drag the damaged trailer about 200 yards further, through the toll booth, and here is where I came to a stop, just beyond the toll…

Luckily, there were some orange traffic barrels not in use nearby, so I was able to make a visual barrier and create a little separation between our rig and the traffic roaring out of the toll booths. The tunnel personnel were very helpful and they were first of many wonderful people I met that day.

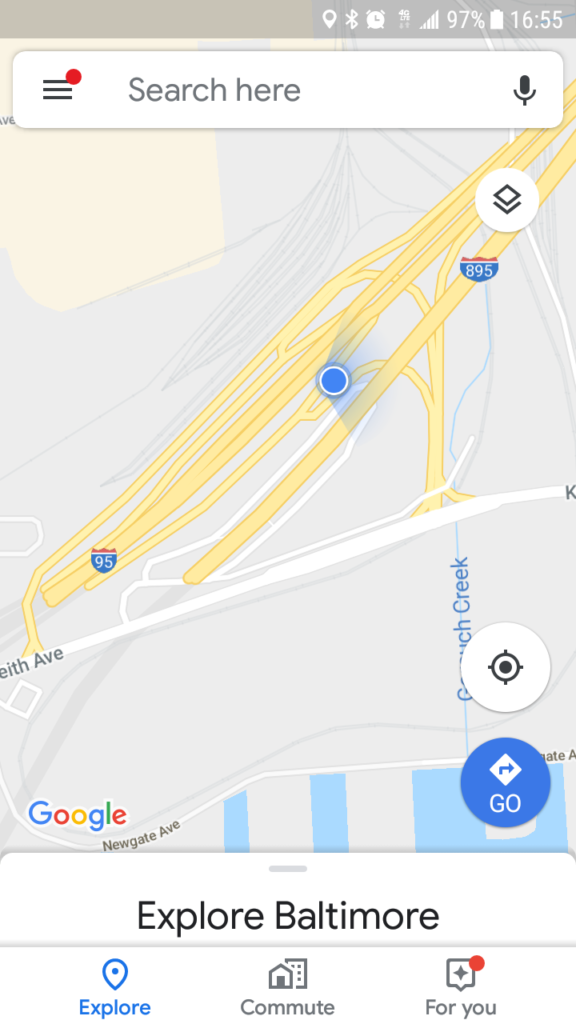

Anyway this is a screenshot of Google Maps showing my precise location just outside the tunnel exit on the north end…

From my roadside position, I called Good Sam roadside assistance, to which Kellyn and I belong as members (an excellent investment), and they came through with a referral to the Okie Truck Service out of Clinton MD, way down southeast of Washington DC. Two mechanics showed up within two hours and they did an amazing job under extremely difficult circumstances. It took three successive repair attempts over the next 6-7 hours, complicated by the fact that the original bracket was a steel alloy, not solid steel, which made welding problematic. First, they just tried to weld it back in place, but that simply would not take. Next, they welded it back in place, and then reinforced it with a steel plate welded to the face of the bracket holding it in place. That broke away again as we were remounting the tires. So for the third attempt, they went all out and welded the bracket back in place, then reinforced it with several pieces of steel that were both welded and then they bolted everything. Just after midnight they completed a repair that held for the next 100 miles to New Jersey…

…as you can see, it isn’t going to hold for much longer, but we’re close enough to multiple repair services to hopefully get the job done in a professional facility, under warranty. These guys from Okie did a fantastic job on a difficult task during a cold night with cars and trucks screaming by at the side of busy I-95. I am deeply grateful for their persistence and professionalism and sheer grace.

While I was waiting for the gentlemen from Okie to arrive, it occurred to me that, if they should fix the leaf-spring bracket mount, I would still have two ruined tires which I guessed wouldn’t last the first hard jolt. So I needed two new RV tires. On a Saturday night. In the middle of Baltimore. On the side of I-95. Sure.

I looked on Google Maps for a nearby tire service and on the second call found the Mr Tire location on 3933 Erdman Avenue in Baltimore, less than 10 miles away.

The manager, Steve, was extraordinarily helpful and professional, and he had the correct tires in stock, which was really lucky because they are not a common size at ST235/85R16. It was approaching closing time (7:00pm), but Steve assured me that he would stay open if I could bring the two tires to him. He said he knew I was stranded and he would do what he could to help.

I finally got to the Mr Tire around 8:15pm, and the tires were mounted and balanced in less than an hour. We chatted, and I learned more about what wonderful people worked at that location with Steve, and I can only say that Steve himself is a person to admire.

Long story short, I am so very grateful for the grace and professionalism of Steve and his team at Mr Tire. It was another long hard Saturday at work for them, but for me it made all the difference.

Eventually, I finally got rolling again around 1:00am. Not wanting to tempt fate with the bracket repair that had already failed twice, I drove at a sedate 40-50 mph for the remaining 100 miles to the campground in New Jersey.

I met some wonderful people last night. The team at Good Sam roadside assistance were professional and persistent. They made the arrangements for Okie Truck Service, and they kept calling back to ensure that the team arrived and the work got started, and that the repair was finished.

The two gentlemen from Okie Truck Service were relentless and resourceful. At 8 tons, the trailer turned out to be too heavy for one of their jacks and it blew out, so they improvised and kept at it. In addition, they had to make three attempts to repair the bracket mount, and the third one did well enough to get me to my destination. Which was just as well, because these poor guys were exhausted, wiped out, after the third repair. Worse still, they said they were then on their way to repair a broken-down tour bus, surely another exhausting rescue.

And Steve and the team at Mr Tire went above and beyond in all respects, staying several hours past closing time on a Saturday night to assist a stranded traveler. Self-deprecatingly, Steve explained that he’ll always stay open when more business comes knocking, but there was undoubtedly more to it than making money.Thank you, Good Sam, Okie Truck Services, and Mr Tire. Kellyn and I are indebted to you all.

Update on Sunday 07-April 2019…

We have spent the past two weeks working with warranty support from the manufacturer of the RV, Highland Ridge RV, and their supplier for the chassis, Lippert Components.

Because we are not sure how long the temporary repair to the mounting bracket will hold, we are reluctant to move the trailer. So, this means we need to find a mobile welding technician to come onsite at our campground.

Such people are not easy to find, needless to say. For example, through a referral from the local Camping World, I spoke with the boyfriend of someone who works there who “does welding”. I sent this person photos of the work, and he responded that he would be able to complete the job for $400. Given that we paid the roadside guys $1250 for a temporary patch job, I have zero confidence that this guy knows anything other than how to turn on his welder. No thanks, dude.

After some calling around, I found a mobile welder whom I have grown to trust, but this guy is so incredibly busy that he is difficult to pin down. He finally made it out to the trailer to evaluate the damage, and he was confident he could fix the failed bracket and move the axle back into its proper position. This will require lifting the trailer off the ground entirely, not an easy job outdoors.

The problem is, we scheduled for him to do the work on Friday 05-April, but he was unable to do so because he was so busy. In fact, he did not respond to any of my attempts to contact him that day. Not good.

So, I went back to one of the first local RV repair services I contacted, Bornmann’s RV. They had told me straight away that they do not have a mobile welding unit, so they could only do work at their facility in Glassboro NJ, about 12 miles away. Disappointed with the mobile welder for dropping off the planet, I called Bornmann’s back and proposed the risk of taking the trailer to their facility to get the work done. The owner asked for photos of the damage so he could assess it first. So passed a disappointing Friday…

The following day, Saturday 06-April, Kellyn and I drove down to Glassboro to visit Bornmann’s. There, the owner candidly told me that we should get a new trailer. His reasoning was convincing.

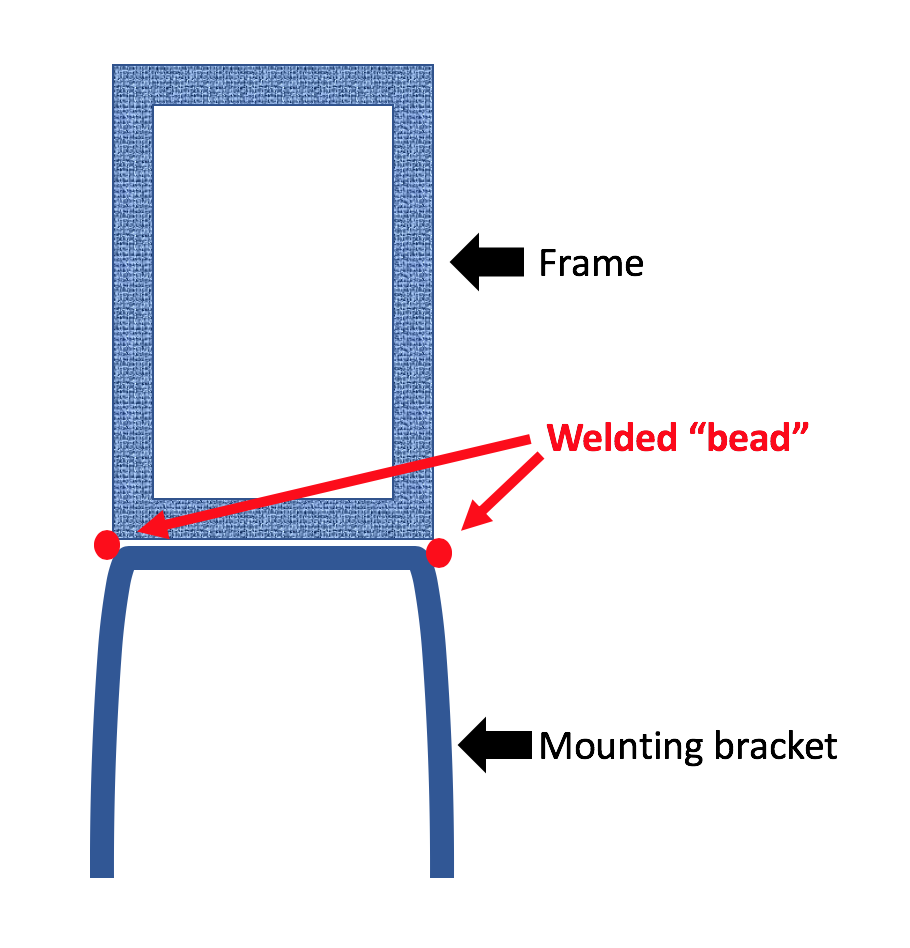

First, from the photos I had sent, he showed me that 1) either the mounting bracket had been welded incorrectly, or 2) the mounting bracket itself was defective. The bracket itself is “U”-shaped, upside down with the cross-bar of the letter “U” welded to the frame of the trailer. In the photo below, it is clearly visible that the welded cross-bar of the “U”-shaped bracket did not pull away from the trailer frame, but rather that the “arms” of the “U”-shaped bracket broke away from the “cross-bar”…

See how the arms are actually severed? If you look closely, you can see the cross-bar of the bracket still attached to the frame. The weld held, but the bracket failed.

What would cause the bracket itself to fail, rather than the weld? There are two possibilities, according to the experienced and certified welders at Bornmann’s. First, it is obvious that the original welder, instead of merely welding the two pieces of metal together, actually cut into the bracket at the angle between the crossbar and the arms.

Here is a diagram showing what happened…

In order to attach these two pieces of metal together, a welder has to run a “bead” of metal along the outside of the base bracket, where it meets the frame, like this…

This bead of additional metal should be laid at the junction of the two pieces of metal, melting some of both into one another to make them into one piece.

Obviously, if the metal is being melted to join them, then a welder must be careful not to heat the metal too high, otherwise they will melt through one or both pieces, effectively cutting them. The difference between a cutting torch and a welding torch is mostly a matter of temperature; they are the same mechanism. So an inexperienced or careless welder will have the torch or rod too hot, melting everything and deforming the objects, instead of merely joining them.

And that is what we see in the photograph above. The arms of the bracket did not rust or deteriorate. They were severed from the crossbar.

The second possibility cause of the bracket failure is that the bracket may have been low-quality steel. High-quality steel is consistent in density and composition, with no soft spots or hard spots. The inconsistency of low-quality steel could create a component like a welding bracket with built-in weak spots, perhaps at the angles between the arms and the crossbar.

The third possibility, of course, is both of the first two possibilities occurring together. With low-quality steel, the margin of error for a welder narrows considerably, so even an experienced technician might cut rather than weld.

What is really troublesome is that whatever was done with one of the six mounting brackets of this sort, could very well have been done with all of them. Not to mention other welding points throughout the chassis.

So, in the opinion of these experienced and certified metalworkers, the frame of our trailer almost certainly has other welds waiting to fail soon, and they recommended that we request a new trailer under our warranty.

Needless to say, this put a bit of a damper on an otherwise lovely weekend. We are stuck in Clarksboro NJ for the foreseeable future, and we are considering our options.

Please stay tuned for more updates…

Update on Monday, 08-April 2019…

So remember when I mentioned that we had found a local mobile welder whom we had grown to trust? That he was scheduled to come do the work on Friday 05-April, but didn’t show up. Yep, a really busy guy, and today we found out why…

He does awesome work. Plain and simple.

His name is Fran and his business is called Vell’s Welding and Services in Paulsboro, NJ. He and his colleague Mike showed up at the campground at around 3:00pm, and they immediately set to work. They came, they saw, and they conquered, and this is what the damned mounting bracket looks like now…

They removed the earlier patches, then maneuvered the axle back into its proper position, and welded the bracket back in place. But, to reinforce it, they cut two pieces of quarter-inch steel plate into triangles, and welded them to the arms of the bracket and to the faces of the frame.

I expect this repair to outlast doomsday.

So, unless something else breaks, we’re going to be good to go this week!

Thanks for everybody’s good wishes!

Whoa. Thank God it failed in that way, and not in a way that caused much worse damage. Whew! Glad y’all are okay.

HOLY COW! I was on the edge of my seat reading this! You are resourceful in finding help when needed! And then you detailed the entire experience with pictures! Awesome!

Stay safe!!